How to Store an Electrical Rubber Matting Roll in Extreme Heat?

Are you struggling to preserve the quality of your electrical rubber matting roll in the extreme summer heat? The struggle can be four-fold more when you are in the UAE or any of the GCC countries.

Are you worried that improper storage of the rubber matting electrical safety might compromise its performance? If you have already bought insulating floor mats in bulk, your entire investment can go in vain. An electrical insulated mat is a safety equipment; it has no value without effective insulation resistance.

Wondering about the best practices for storing an electrical rubber matting roll in the summer?

You’re not alone. Electrical contractors, facility managers, and safety officers worldwide often face similar challenges.

In areas where summer temperatures soar above 45–50°C—such as the Middle East and Indian states like Rajasthan, Gujarat, and Maharashtra—improper storage can severely affect matting performance.

In this blog, we will explore easy ways by which you can store your electrical rubber matting roll during the summers and ensure long-term rubber matting electrical safety in the intense heat.

Why Proper Storage of Electrical Rubber Matting Roll Matters?

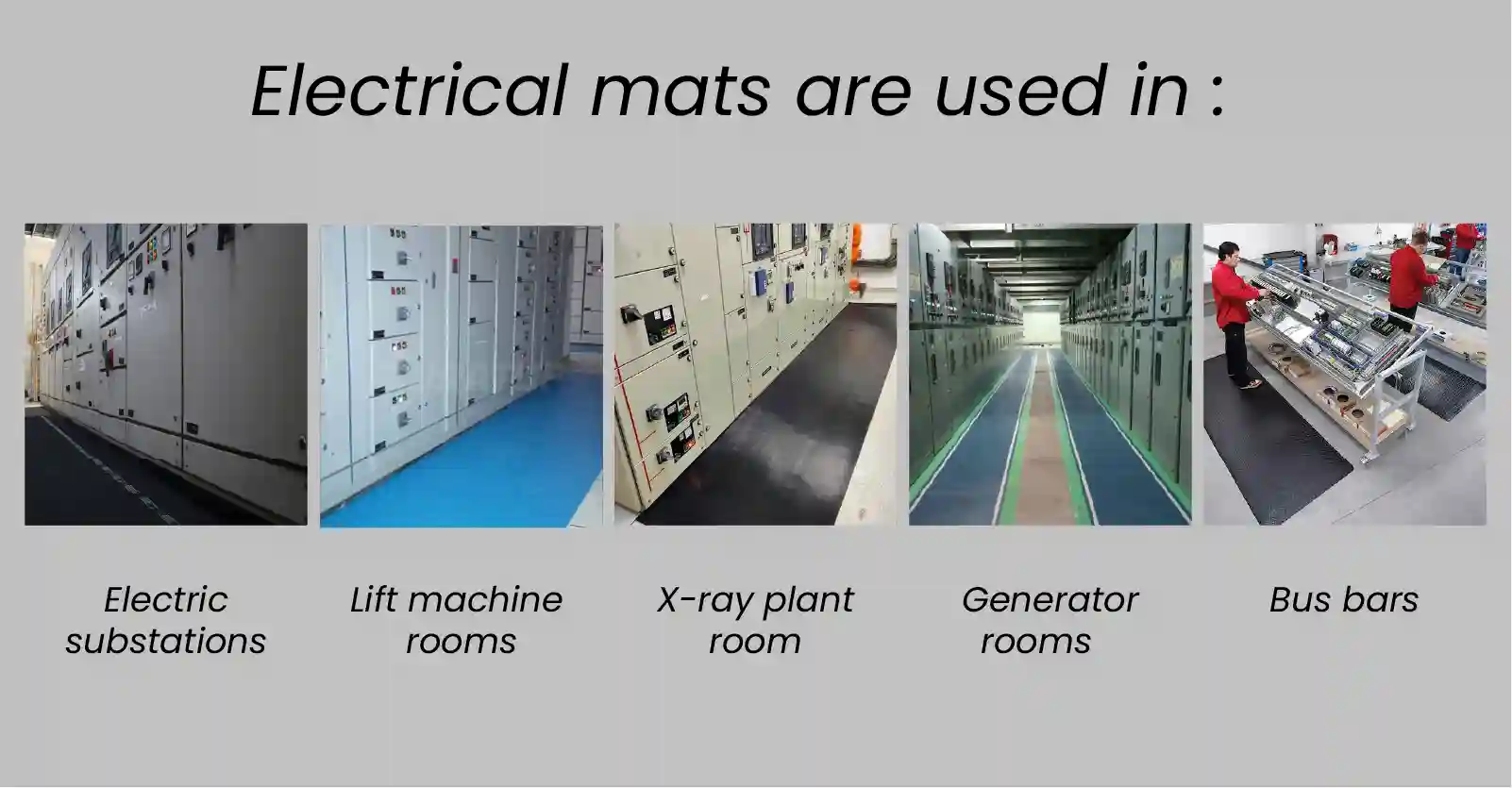

A rubber mat for panel room is available in IEC 61111:2009, IS 15652 and ASTM D178 standards. It is used near high voltage equipment.

It is a vital safety equipment designed to provide safety to personnel working near high electricity. Extreme heat in UAE, Saudi Arabia, Oman, Qatar, and parts of India can lead to:

- Cracking and deterioration

- Loss of flexibility and dielectric strength

- Fast aging and surface degradation

Even the top-quality insulating floor mats can break down if they are stored improperly.

Nevertheless, if you store your industrial equipment correctly, you will also get a few advantages like:

- Improved workplace safety

- Maximum space utilization

- More productivity

- Accurate inventory management

- Reduce OPEX (operational expenses)

4 Common Risks of Improper Storage of Insulating Floor Mats

Improper storage of electrical rubber matting roll exposes it to several risks. During the summer, the heat and humidity are the main enemies of the insulating rubber material. The top four risks of them are:

- Constant exposure to UV rays accelerates material breakdown.

- High surface temperatures weaken insulating properties.

- Folding or incorrect rolling causes stress cracks in the rubber matting electrical safety variants.

- Storing rubber mat in electrical room near chemicals or oils leads to contamination and damage.

Best Practices for Storing an Electrical Insulated Mat During Summers

Summers call for extra protection in every aspect of your life. The government of every country issues a summer special guideline that demonstrates ways to keep safe during this extreme period. Similarly, you have to treat your industrial equipment especially when there is high heat outside.

You can practice these if you want to store your rubber mat flooring and retain its originality:

1. Keep the electrical rubber matting roll in a cool, shaded area

In an industrial set-up, it is impossible to maintain an optimum temperature throughout, especially near the production floors. In mining, metal refining, construction, or electricity generation industries, there are operations that generate high heat.

Therefore, if you have already bought your insulating floor mats in bulk and are looking for easy ways to store them, first find a cool-shaded spot.

Avoid exposure to sunlight and heat-prone areas. Indoor storage with proper ventilation or climate control is ideal. In Indian warehouses or GCC utility buildings, maintaining storage temperatures below 30°C can significantly extend mat life.

2. Keep the rubber mat roll horizontally

We advise you to keep the electrical mats in their original package if you have a space crunch. However, do not keep the rolls in a standing position i.e. horizontally as it can make the bottom edges warp.

Horizontal placement of the rolls preserves the qualities of the rubber matting electrical safety.

3. Never fold the electrical insulated mat

When do users fold an electrical insulated mat? The answer is when they do not fit in. Suppose you have to place a rubber mat for panel room in a narrow area. What will you do if you find out that the electrical mat you are using is just an inch bigger than the surface area? Stuff the mat anyway?

No! Rather, you should get electrical rubber matting roll in the sizes that are required. Similarly, what will you do when you find that you do not have a storage area as big as the mat’s dimension? Do not fold the mat to make it fit the space.

Folding stresses the material and compromises rubber matting electrical safety. Always roll mats loosely and evenly.

4. Use UV protective covers for the rubber mat roll

You cannot control the direction of UV rays during the summer. While we always advise keeping electrical rubber matting roll away from the sunlight, we understand it can be difficult at times.

In such cases, you can use a UV protective cover for safeguarding the electrical rubber matting roll.

Store the mat inside a UV-resistant bag, plastic wrap, or cardboard tube to shield it from light, dust, and moisture.

5. Avoid placing the electrical rubber matting roll near heat-emitting equipment

Heat-emitting equipment refers to devices such as radiators, boilers, gas furnaces, electric heat pumps, etc. When you are storing the electrical mats, make sure they are away from these devices. High heat can degrade rubber fast, making them hard and brittle. Radiant heat also leads to mat fatigue.

How to Use Rubber Mat in Electrical Room Settings?

Many users still have the question ‘How to use rubber mat in electrical room’ correctly. Well, according to industry specialists, the best practice to use a rubber mat in electrical room in both GCC and Indian industrial environments is below:

- Lay mats flat in front of panels, switchboards, or busbars.

- Ensure full coverage of operator standing zones.

- Inspect regularly for cracks, cuts, or discoloration.

- Clean mats with mild soap and avoid harsh chemicals.

- Secure mats with anti-slip backing if necessary.

Wrapping up,

Whether you are operating in the Middle Eastern countries or high-temperature regions in India, proper storage of your electrical rubber matting roll is crucial. It will protect the investment that you have made when you have bought the mats in bulk.

Looking for durable insulating mats suitable for India and the Gulf?

Connect with our team for expert advice and certified solutions designed for harsh environments.