When is an Electrical Safety Rubber Mat Not So ‘Safe’?

An electrical safety rubber mat is popular as personal protective equipment- a safety gear. By reducing the chances of electrical hazards, the electric safety rubber mat is a favorite among users for hassle-free installation and complete assurance.

However, what if we say that your rubber ‘safety’ matting might not be ‘safe’ always? Let’s visit some scenarios that compromise the effectiveness of the electrical safety rubber matting:

When an Electric Safety Rubber Mat is Not So Effective: The Danger Zone

If you are a user of an electrical safety rubber mat, you must have doubted its efficiency at least once! How do you know the electrical panel safety mat is working?

While it is quite natural to have such questions, if the safety electrical rubber mat becomes unsafe- you should worry about it.

These situations compromise the safety of the electric safety rubber mat:

Non-compliance with the Electrical Safety Standards

An electric safety mat should comply with either global or local electrical safety matting regulations. As of now, there are IEC 61111:2009, IS 15652:2006, and ASTM D178 compliance standards are the most popular.

Electrical mats that fail to meet the parameters of safety laid out in the guidelines lack the required dielectric strength. Furthermore, they might have optimum insulation resistance, durability, or enough resilience.

Non-compliance in rubber safety matting occurs due to:

Thus, you should always go through some essential documents that validate the compliance of an electrical panel safety mat. A manufacturer’s certificate and a third-party testing certificate are two such documents.

Incorrect Electrical Safety Mat Voltage Rating

Each electrical safety matting is designed to withstand a specific voltage range. For example, we suggest you use an electrical safety matting 1000v for voltages up to 1 kV or 1000 Volts.

Using a mat rated for lower voltage in a high-voltage environment is a critical mistake.

You should regularly assess the voltage requirements of your workspace and ensure the mat’s rating aligns with these needs.

Physical Damage to the Rubber Safety Matting

Most users neglect physical damage to the safety mats. They think that a slight crack or a curled edge does not make a difference. Wear and tear significantly hampers the performance of an electrical panel safety mat.

In an internal survey, we have found that approximately 68.14% of users find that common issues include:

Improper Storage and Maintenance

How well you store the electrical mats matter the most. Regular users prefer to buy safety mats in bulk. This saves cost and money. Additionally, some resellers buy and stock electrical safety rubber mat variants in large quantities. Now, if you do not know how to store the products, you will end up with a big monetary loss.

Worry not! This blog covers the most frequently asked questions of rubber insulation mat users- how to store, inspect, and transport the mats.

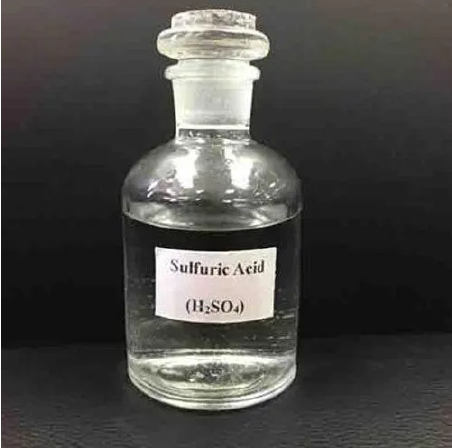

Use in Unsuitable Environments

An electric safety rubber mat is usually very durable. They can withstand high temperatures, heat, chemicals, and oils. Nevertheless, using them outside their intended environments can lead to failures:

Hence, if you have to install the electrical mats near corrosive chemicals or constant heat, you may have to customize them.

Neglecting Routine Testing

Routine testing is a must for safety equipment, especially when it promises you electrical safety. Over time, even the best electrical mats require timely inspection. You can do it in two ways:

Counterfeit Electrical Safety Rubber Mat

The market is flooded with counterfeit or fake electrical safety mats. These products may seem similar to the genuine products, but they are not.

Counterfeit safety mats are unsafe to use. They can get you into legal trouble also.

Top 10 Electrical Dangers that an Electric Safety Rubber Mat May Prevent

Do you know more than 1000 people die from electrocution every day, according to the HSE? There might be as many as ten dangers lurking around you when you are not thinking about elevating the safety measures at your workplace:

And, you can prevent up to 95% of electrical accidents by using an electrical safety rubber mat and staying cautious!

An electrical panel safety mat can be a lifesaver—but only when it meets standards, is used correctly, and is maintained well.

When in doubt, consult the experts. Looking for a rubber safety matting expert? Reach out to us!