15 Surprising Stats & Facts about Insulating Mats You Need to Know

Is your workplace dealing with live electrical equipment well-guarded from electric shocks? Did you have an insulation mat applied on the floor where live electrical equipment is placed? Are you aware that an electrical rubber mat plays a significant role in ensuring the safety and security of electrical operators?

Usually laid down on the floor in front of the electrical panels or equipment, there are more surprising facts about insulating mats that one should know. According to an article published in ‘The Hindu’, more than 40% of fire accidents in buildings occur due to electrical hazards. In addition to it, close to 13 electrocution fatalities happen on an average day in India because of workplace accidents. On the other hand according to a HSE report, around 25 people die of electrical accidents at work with 1,000 electrical accidents happening every year.

You may not know everything about insulating mats. Check if you are aware of these 15 surprising facts about your most trusted electrical safety gear or not!

15 facts about electrical insulating mats that you may not know

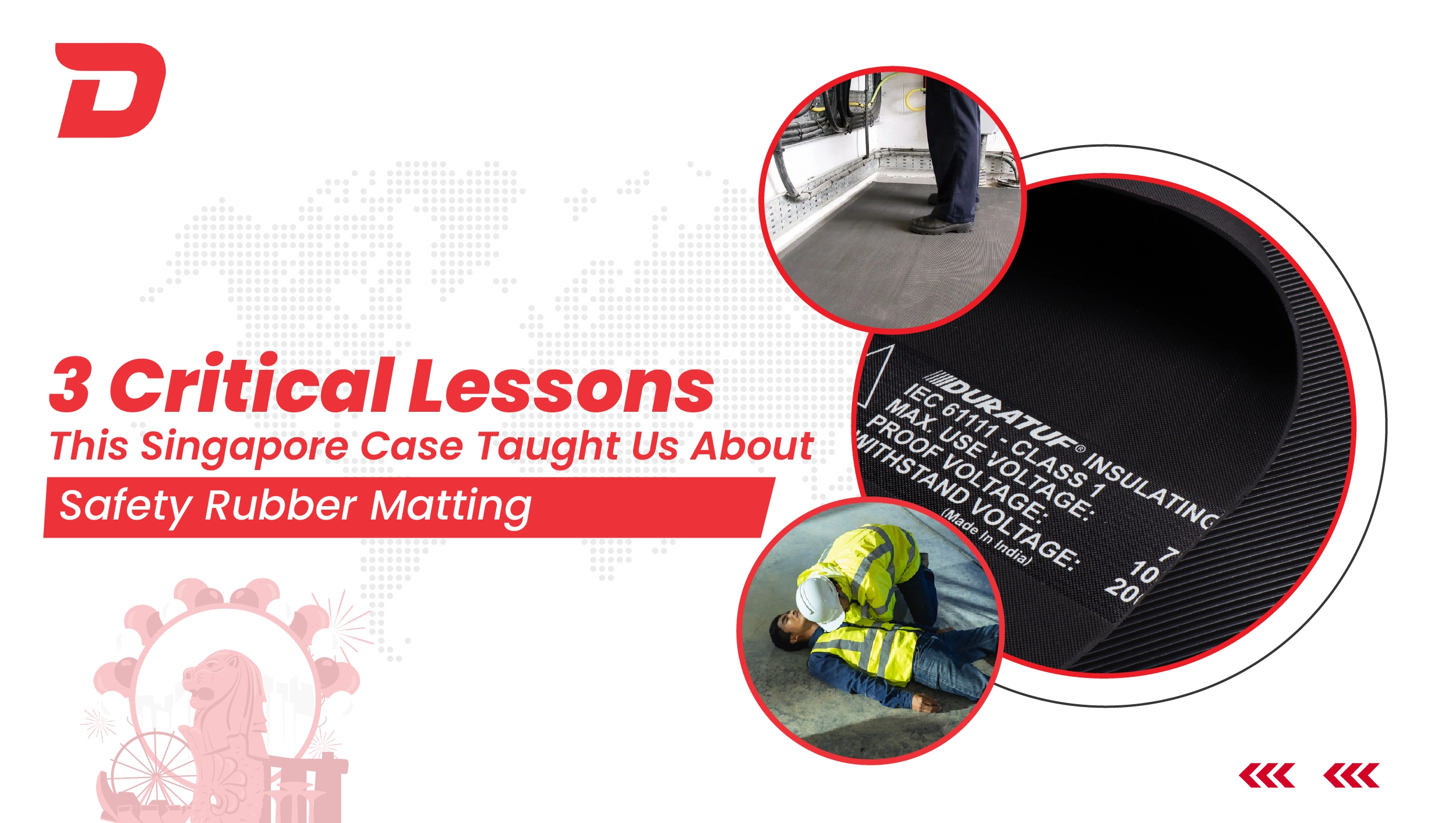

Insulating mats act as protective gear for electricians, technicians, and laborers who work on live electrical equipment in the workplace. In addition to providing enhanced levels of protection for workers, they prevent important essentials and electrical assets from being damaged due to unexpected electrocution or fire.

1. Electrical Insulating Mats are Non-Conductive in Nature

The electric mat is made up of synthetic polymers that provide better non-conductivity. It obstructs the electrical energy to flow from the electrical source to the earth via the human body.

Rubber’s molecular structure prevents the free movement of electrons. Hence, the insulating mat electrical resists the flow of current through unintended paths. Rubber has electrical resistivity of 10^12 to 10^16 Ω⋅m.

2. Insulating Mats are a Mandatory Requirement

There is no question of whether you want to install a rubber mat for the electrical panel room since it is a mandatory requirement. To ensure safe working practices in enterprises that make use of heavy power equipment, it has become a mandatory safety parameter that enterprises should adhere to.

3. Insulating Mats are Available in Various Colors

Are you bored with the usual black-colored insulation mat? A premium quality electrical mat that adheres to the latest Indian standards IS 15652:2006 such as X-Volt insulating mats for electrical purposes. and Safevolt insulation mats are available in custom colors depending on the user requirements. You can choose between blue, red and black colors. The option to choose from different colors also makes it visually appealing.

4. Electrical Insulating Mats are Cost Effective

If you have thought of purchasing a top-quality electrical mat, then affordability becomes a concern. Duratuf has a range of electrical rubber mats to choose from at a surprisingly affordable price tag without compromising on the quality and safety standards.

However, insulating mats for electrical purposes require minimal maintenance. They require regular cleaning, visual inspections, and periodic checking. It also has high durability and longevity, which saves you from heavy maintenance costs. Thus, you can say that they are cost-effective in the long run.

5. Insulating Mats Enhance the Comfort of the Electrical Workers

The smoother yet sturdy design of the electrical rubber mat ensures the utmost comfort for the electrical workers and technicians without them being tired of standing for long hours. The cushion-like surface offers enhanced convenience for the workers. Thus, an insulation mat helps increase the overall productivity of the electrical worker.

6. Electrical Insulating Mats are Easy to Install

Irrespective of how complex the huge electrical equipment is in your enterprise, the installation procedure of insulating mats for electrical purposes is seamless and hassle-free. All you have to do is place the electrical rubber mat on the floor in front of the position where the large electrical equipment is placed and electrical workers or technicians have to stand and work.

- Clean the floor and dry the floor

- An adhesive will be applied to the floor

- Then place the insulation mat

The roller application will be applied for pasting the electrical rubber mat onto the floor

7. Insulating Mats are Resistant to a Wide Range of Temperatures

The aging properties of insulation mat are among the best in its class. They deliver the best resistance during high insulation as well as very low-temperature resistance. IEC 61111:2009 compliant electrical mats can withstand -25 degrees to +55 degrees centigrade temperatures. Besides, IS 15652:2006 electrical mats can endure -10 degrees to +55 degrees centigrade temperatures.

8. Electrical Insulating Mats Come in Different Shapes and Sizes

Rubber mats for electrical panel rooms are available in different sizes and shapes according to the user’s specific requirements and also depending on whether the user is purchasing the electric mat for small, medium, or larger enterprises.

9. Insulating Mats Have Extensive Applications in the Industries

The application area of an electric mat includes a wide variety of electrical fields such as,

- Switchboards

- Power Plants

- Power Transmission Rooms

- Electrical Substations

- High Voltage Panels

- Within the Lift Control Gear Rooms

- Areas where electrical technicians will have to work on the opening of the electrical panels as well as wires

10 Electrical Insulating Mats Have High Durability

An electrical rubber mat of premium quality is durable in its characteristics. It is up to the user to ensure the electrical mat they purchase adheres to safety standards and whether they are BIS-approved or CPRI/ERDA-tested. Approval from third-party testing agencies indicates the electrical mats are of premium quality and are long-lasting as well as high voltage resistance.

The durability of Safevolt insulation mats can be anywhere between a minimum of 8 years and a maximum of 10 years. The durability of X-Volt insulating mat electrical durability may range anywhere from 5 to 10 years. The standard warranty of IEC 61111:2009 and ASTM D-178 compliant insulation mats is 12 months. On the other hand, it is 12 months for X-Volt insulation mats. However, the durability depends a lot on how carefully the user is able to maintain these premium-quality insulation mats.

11. Insulating Mats are Easy to Clean

Electrical rubber mats can be easily washable. No matter how much dirt or dust is stuck in the mat, it comes off easily after a wash allowing the user to keep it clean always.

12. Electrical Insulating Mats are Flexible

Electrical mats are designed to be flexible. The flexible characteristics allow the authorized professionals to install it in the electrical areas with ease for keeping the area shockproof.

13 Electrical Insulating Mats Minimize Physical Accidents

Primarily, insulating matting is used to ensure electrical safety. But did you know it can minimize the risks of physical accidents in the workplace?

An electrical insulating rubber mat has an anti-skid design. It may come with a ribbed or a dotted texture. As a result, this increases the traction of the workers’ feet to the ground. It prevents the workers from slipping and falling.

14. Electrical Insulating Mats Have Remarkable Tensile Strength

Electrical mats or insulation mats feature better tensile strength compared to electrical checker mats. The ASTM D-178 compliant mats have a minimum tensile strength of 15 MPa. Besides, IS 15652:2006 compliant mats have tensile strength of 4.83 MPa.

15. Insulating Mats Do Not Get Damaged With Oil Exposure

Insulation mats are designed to be highly oil-resistant. It is also acid-resistant and alkali resistant. This entire feature makes it a preferred choice among users.

In a nutshell,

Rubber mats for electrical panels are non-conductive and have high dielectric strength. In addition to electrical safety, they also ensure the physical safety of the workers. Their resistance against a wide range of temperatures, oil, mechanical stress, and others contributes to their high longevity.

In addition, rubber mats for electrical safety are easy to maintain and install. As a result, it does not require additional expenses. A superior-grade electrical rubber mat is your ultimate solution to ensure complete electrical safety for your workers and technicians as well as comply with electrical safety regulatory norms initiated by the government.