15+ Tips to Safely Work with High Voltage Equipment: The IEC 61111 Mat

Even the most experienced professionals may face a deadly accident if the electrical safety measures are not in place. Whether you are a first-timer or an experienced professional- there is no foolproof way to handle electricity.

However, there are ways in which you can reduce the risks to some extent. One of the easiest ways to do that is to use a safety-compliant PPE like an IEC 61111 mat. Nevertheless, our specialists say that using the IEC 61111 standard mat alone might not be sufficient.

So, how can you ensure that you are doing everything possible to keep the electricity-related dangers at bay? Simple! Reading this blog that contains 15+ tips to work safely around high-voltage equipment.

15+ Tips on Electrical Safety and Using the IEC 61111 Mat Correctly

Accidents cannot be 100% avoided. They are unpredictable. However, the numbers can be reduced by following these safety tips:

#1 Choose the Right IEC 61111: 2009 Electrical Mat

The electrical mats are quite popular among across various core industries. Nevertheless, it is also true that many people are unaware of the right class of the electrical insulating rubber mat 61111. Since a Class 0 and Class 1 IEC 61111 rubber mat is cheaper, some users go for those mats- thinking they are ‘still using an electrical mat’.

On the contrary, many buyers purchase thicker higher class (Class 3 or 4) IEC 61111 insulating matting believing thicker mats will provide more insulation.

While both points of view are partially correct- this is where you might be exposing yourself to an electrical accident. First, you will have to understand the type of IEC 61111 mat you need. If you are confused, get expert help.

#2 Inspect IEC 61111 Standard Mats

Electrical insulating mats have a limited lifetime- no matter how superior the quality of the mats you have. Duratuf IEC 61111 2009 mats last up to a minimum of 5-6 years with little maintenance. As the mats go old, their electrical insulation capacity degrades. The edges may get folded or warped as well.

Therefore, you should visually inspect the electrical insulating rubber mat IEC 61111 periodically. Believe us, inspecting an electrical mat is not at all a time-consuming process!

#3 Keep the IEC 61111 2009 Mats Dry

Water is a good conductor of electricity. Therefore, if the electrical mats are wet, it might hinder the electrical insulation capacity of this safety equipment. Although, in some industrial applications, the electrical mats get exposed to water. Sometimes, the rubber mats soak moisture from the floors beneath.

Thus, before buying an electrical rubber mat, check if it is water-retardant. Moreover, if the mats become wet, they should be wiped down and dried completely.

#4 Place the Mats Rightly

Electrical mats are laid on the floors in front of high-voltage machines like control panels, transformer units, switchboards, HT-LT panels, etc. IS 15652 standard electrical mats are lighter; they should be fixed with adhesives. However, an IEC 61111 standard or an ASTM D178 electrical mat is heavier. Therefore, adhesives are not required to fix them.

Apart from using the adhesives, our experts can help you with detailed installation guidelines.

#5 Follow Electrical Diagrams and Labels

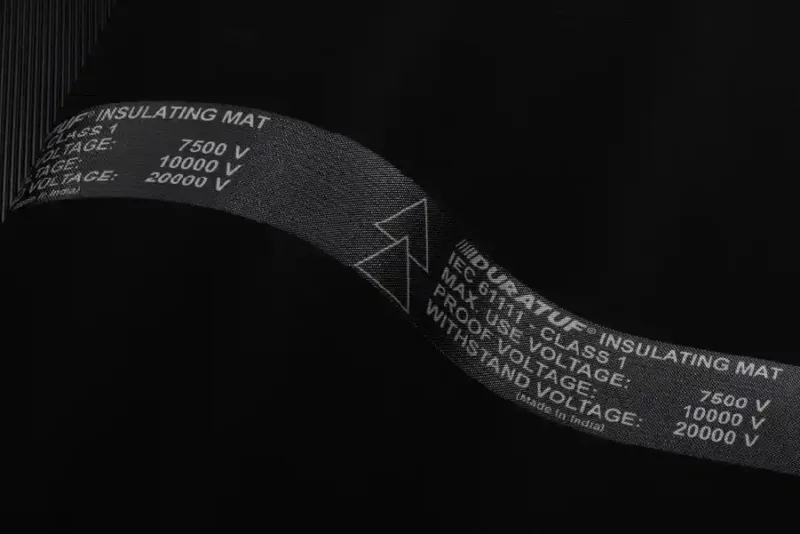

Diagrams and labels work as a manufacturer’s manual about correctly using a specific electrical instrument. It is inconvenient for the workers to keep following the detailed guidelines like an IEC 61111 insulating matting pdf while working. Therefore, electrical machines and personal protective equipment have a gist.

You will find product labels on your electrical insulating rubber mat IEC 61111 that contain vital information about the class, batch number, and other details

#6 Store the IEC 61111 Mats Properly

Do you think bulk buying the IEC 61111 standard mats is economical? Yes, our specialists also recommend bulk buying them as the more the quantity, the more discounts you will get. Nevertheless, once you buy electrical mats in greater numbers, ensure they are stored appropriately.

Keep the electrical mats away from direct sunlight, high temperature, and corrosive chemicals. Store them in their roll packages or lay them flat.

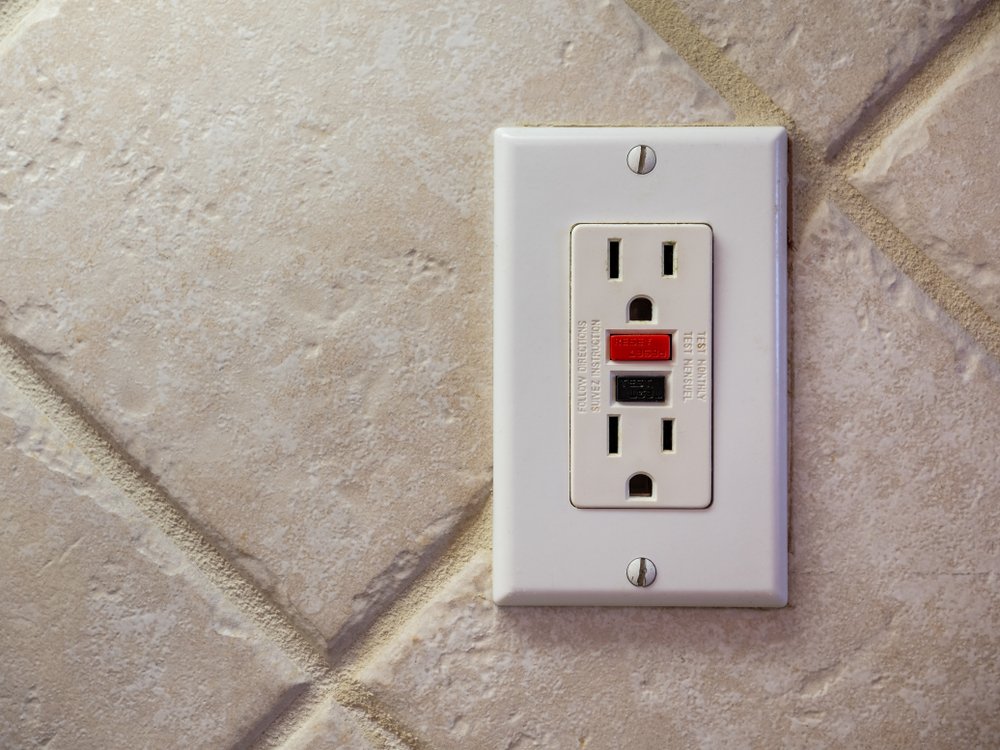

#7 Use Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters detect a ground fault and immediately shut down the electrical circuit- disconnecting the power. If your workplace has sensitive high-voltage areas, then along with using an IEC 61111 mat, you should use the GFCIs.

#8 Wear Appropriate Personal Protective Equipment (PPE)

An IEC 61111 standard mat is a reliable PPE but it should be used with other safety gears like electrically insulated gloves, rubber-soled boots, flame-resistant clothing, face shields, and arc flash protection gear. When you are working near a high-voltage machine, you must take full body protection to maintain maximum protection.

#9 Use Insulated Tools

Insulated tools are specifically designed for high-voltage environments. They are made of non-conductive materials like glass or plastic or they have grips made of rubber. Insulated screw divers, pliers, or hammers provide an extra layer of protection against electrical shocks.

#10 Lockout/Tagout (LOTO) Procedures

The LOTO procedure is a safety protocol that prevents the workers from being accidentally injured by high-voltage electricity. This ensures the equipment is de-energized and cannot accidentally be switched on while maintenance or repair work is in progress.

#11 Maintain a Safe Distance

Even if you are wearing a non-conductive body suit, standing on a quality-certified IEC 61111 electrical mat, and using insulated tools- you should still maintain a safe distance from the high-voltage machines. A safe physical distance ensures that you are not too close to the electrical field of the machine.

#12 Regularly Inspect Electrical Equipment

Just like you inspect an IEC electrical insulating rubber mat 61111, you should periodically test the electrical equipment too. You can arrange for a safety inspection at your industrial facility to make sure there are no faulty cables, or loose or broken wires. However, you should be a certified professional or hire one to carry out the safety inspection. It is not as easy as inspecting an IEC 61111 2009 electrical mat.

#13 De-Energize Equipment Whenever Possible

De-energize electrical equipment before working on it, if possible. You or your workers should work on live equipment only when it is absolutely necessary and with extreme caution. In this regard, de-energizing systems are the safest way to perform maintenance or repairs.

#14 Inform Your Team About Emergency Procedures

If you are in charge of managing an industrial facility, you will have to take charge of educating the people working there. Ensure that all personnel are familiar with the emergency procedures in case of electrical accidents. Some procedures include performing CPR and the use of fire extinguishers rated for electrical fires. Quick and effective responses can save lives during emergencies.

#15 Monitor Environmental Conditions

High-voltage work is more dangerous in extreme conditions such as high humidity, rain, or excessive dust. Be aware of the environmental factors that can increase electrical risks and take appropriate precautions, like ensuring dry conditions or using additional insulation.

#16 Have a Detailed Emergency Evacuation Plan

An emergency evacuation plan or a fire drill highlights the preparedness of an individual when a disaster strikes. It comprises 5-step planning, typically that starts with planning beforehand. You should plan the evacuation routes, assembly points, and communication codes.

The evacuation plan is the last resort to save your workers and resources.

Looking for a safety-compliant IEC 61111 Standard Electrical Mat?

Here’s why you should get them from Duratuf:

To sum up

Working with high-voltage equipment requires a combination of careful preparation, the right protective equipment, and adherence to strict safety protocols. Beyond using IEC 61111 insulating mats, these 15+ tips will help you minimize risks and ensure a safer working environment.