10 Consequences of Not Using the Right Electrical Hazard Floor Covering

When was the last time you looked at the industrial floor where you stand and work? Especially, near the electrical panels? Do you have high voltage insulation flooring there?

Does the electrical hazard floor covering really protect you, or does it only give you a false sense of security?

In industrial facilities, the floors are more than just a surface. It is your first line of defense- specifically near high voltage equipment. Did you know that the Earth is a natural conductor?

This floor can be the weakest link, too, exposing you to life-threatening consequences. Many businesses choose an ordinary floor mat, PVC sheets, or worn-out coverings under high-voltage equipment, believing they are compliant instead of an electric shock protection mat.

The truth is, wrong floor mats come with consequences, worse than you can imagine.

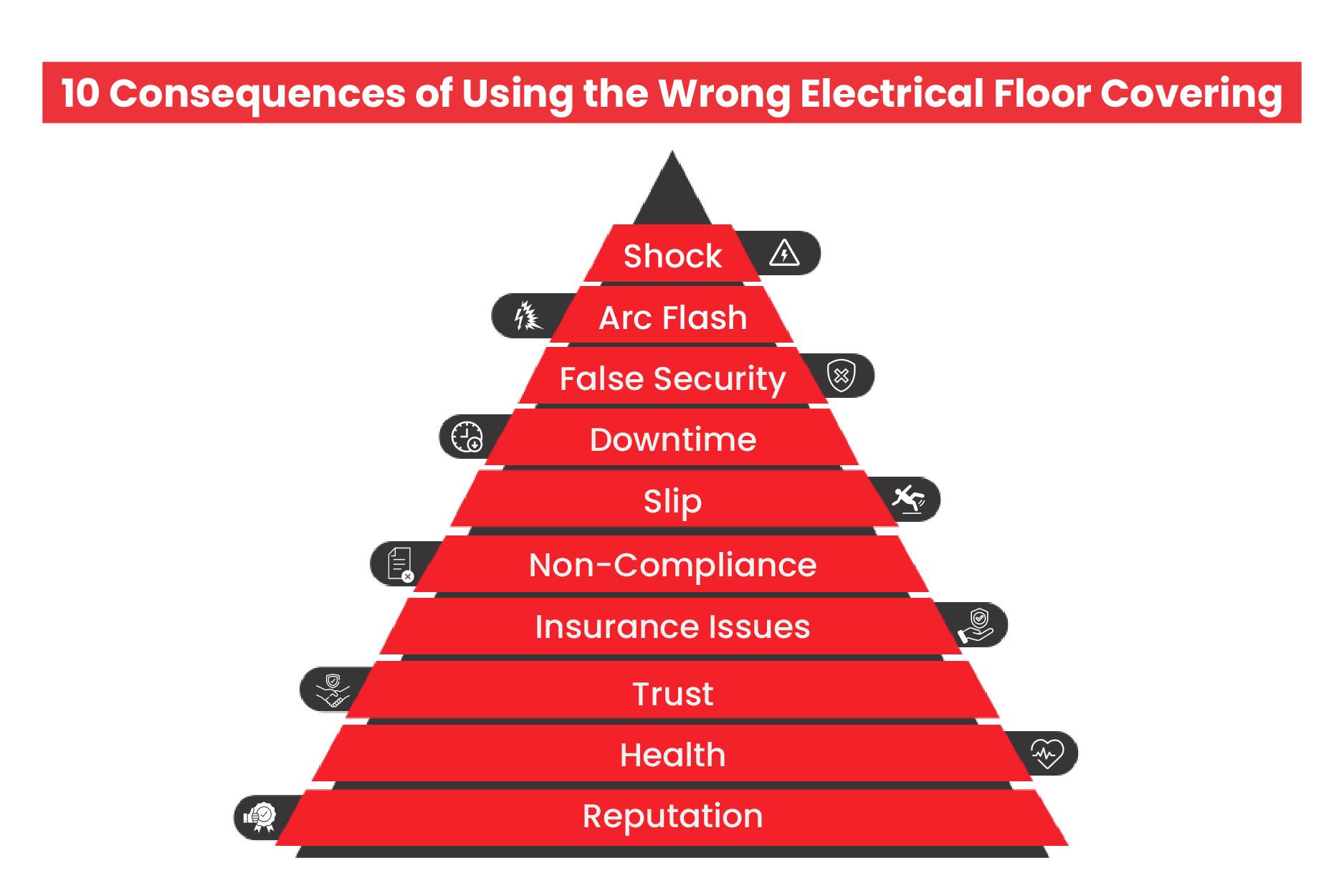

Here are 10 real-world accidents that can happen if you are not using the right electrical hazard floor covering:

10 Accidents that Wrong High Voltage Insulation Matting Welcome

Your arc flash protection matting is the unsung hero, silently protecting you 24/7 from disasters like:

1. Severe Electric Shocks

Electric shock is the immediate risk that one can think of when working near high voltage machines. Industrial machines work on voltages much higher than domestic appliances.

A worker standing on an inadequate floor covering is directly exposed to live current if a leakage or fault occurs. This shock can cause jolts, burns, blisters, and nervous breakdowns. You may be wearing electric protective equipment like gloves, arc flash suits, helmets, etc., but the floor is in constant contact with the body via footwear.

Without appropriate industrial electrical floor mats, this risk can get deadly.

2. Hidden Arc Flash

Arc flash does not just light up in the air. Instead, they spread along the surfaces.

An arc flash is an electrical explosion that results from a fault between two or more conductors. It creates an extremely hot and bright plasma arc that can reach temperatures as high as 35,000°F (19,400°C), which is hotter than the surface of the sun.

Conductive floor coverings, like an ordinary mat or PVC flooring, can add fuel to the fire. On the contrary, an electric shock protection mat with fire-resistant properties can extinguish the fire in less than 5 seconds.

3. False Sense of Security

Cheap PVC mats or regular rubber sheets resemble a dielectric electric shock protection mat visually. Therefore, the workers often mistake them for an electrical hazard floor covering. But they are unaware that the floor mat is not a certified electrical safety gear until an accident occurs.

This psychological trap makes you believe you are safe when you aren’t. This creates more danger than having no mat at all.

4. Unplanned Downtime from Secondary Damage

An accident that is caused by live wires and travels through the flooring surface does not always hurt people. It damages the industrial equipment, as well, causing unplanned downtime.

It can fry sensitive equipment connected to the same grounding system, leading to sudden shutdowns, production losses, and expensive repairs. One wrong mat can jeopardize an entire production line.

However, an electric shock protection mat cannot protect sensitive parts of the machines completely. You need an ESD mat for that.

5. Slip, Trips, and Falls

Slips, Trips, and Falls, known as STFs in industrial language, are one of the leading causes of workplace accidents. A report suggests that approximately 65% workday losses are due to the STFs.

Industrial floors handle heavy traffic, oils, and chemicals. Generic mats or uncertified anti static electrical mats lose grip in such an environment, turning the floor into a death trap. What was meant to protect against electricity ends up being a mechanical hazard, too.

6. Non-compliance Penalties

Workplace negligence can result in various forms of penalties like fines, penal actions, and reputational damage. Electrical safety is regulated by standards like the IEC 61111. IS 15652 and ASTM D178. This is why we have various variants like the IEC 61111 rubber matting, ASTM D178 switchboard matting roll, and IS 15652 electrical mats.

Using uncertified or inappropriate mats can fail safety audits, attract regulatory penalties, or even shut down operations until compliance is restored. Along with this is your reputational damage, with which you lose important clients..

7. Rejected Insurance Claims

After an accident, the insurance company auditors visit the place of the incident to look for compliance with safety norms. If they found you using uncertified high voltage insulation flooring or ordinary rubber mats, they will reject your insurance claim. This leaves your company absorbing massive medical, legal, and repair costs alone..

8. Employee Morale Down

The human resource keeps your industrial operations running. No matter how advanced the machines you have in your industrial facility, you need workers to control those machines.

Workers notice if you are taking the aspects of their safety seriously. A single incident caused by the lack of an electric shock protection mat can reduce their trust in the management.

Employees may feel undervalued, disengaged, or even unwilling to work near high-voltage zones, impacting productivity and retention.

9. Slow Health Damage

An accident need not always be big. Sometimes, you do not realize that you are getting electric shocks from a faulty wire- until it gets too big. Prolonged exposure to micro-leakages through low-quality mats can cause nerve stress, muscle fatigue, and long-term health complications—silent but costly over time.

10. Reputational Damage of your Organization

Reputational damage is the worst of all these risks, having the most long-lasting effect on your business. News of preventable accidents goes viral in minutes. Clients, stakeholders, and the regulators take such news quite seriously. If there are frequent cases of accidents, they can even blacklist your organization.

Reputation takes time to build; once lost, it may take ages. Why take the risk when you can handle it all with a quality-certified electrical hazard floor covering?

Choose Quality-Certified Mats of the Right Class and Electric Shock Protection Mat Standard

Wrong mats can also mean certified anti-static electrical mats for inadequate voltage levels. This is why we have prepared a comparison table for you to understand better:

| Standard | Class | Maximum Working Voltage (AC) | Withstand Test Voltage (AC) |

|---|---|---|---|

| IEC 61111 | Class 0 | 1,000 V | 5,000 V |

| Class 1 | 7,500 V | 10,000 V | |

| Class 2 | 17,000 V | 20,000 V | |

| Class 3 | 26,500 V | 30,000 V | |

| Class 4 | 36,000 V | 40,000 V | |

| ASTM D178 | Class 0 | 1,000 V | 5,000 V |

| Class 1 | 7,500 V | 10,000 V | |

| Class 2 | 17,000 V | 20,000 V | |

| Class 3 | 26,500 V | 30,000 V | |

| Class 4 | 36,000 V | 40,000 V | |

| IS 15652:2006 | Class A | Up to 3.3 kV | 10,000 V |

| Class B | Up to 11 kV | 22,000 V | |

| Class C | Up to 33 kV | 36,000 V |

Still confused? Reach out!

Using the right dielectric mats is not just about compliance; it’s about protecting people, equipment, and your company’s future. Do you need expert help choosing the right variant? Connect with our team now!