Why Do You Need Electrical Rubber Mats in the Marine Industry?

The marine industry, with its intricate web of electrical systems, presents a unique set of challenges and safety considerations. In this dynamic environment, the need for robust safety measures is important. One such indispensable component that takes center stage in high-voltage areas on a ship is the electrical mat.

How Much is High-Voltage in a Ship?

n marine terms, voltage below 1 kV (1000 vac) is considered low voltage. On the contrary, in a ship 3.3 kV, 11 kV, 33 kV, or anything above that is high voltage, demanding the use of a shock proof electrical mat.

However, there is a catch. Since a ship or a submarine has to stay most of the time away from land, they use a complex network of electrical systems. Such complexity is rarely seen in an application on land that might use the same amount of electricity.

A rubber mat for electrical panel is therefore indispensable in the marine industry. Nonetheless, if you are thinking about electrical rubber mat price, you need to be prudent while choosing.

Shock-Proof Rubber Mat: An Overview

When it comes to electrical safety in the marine industry, shock-proof rubber mat or a rubber mat for electrical panel is an unsung hero.

This electrical mat is specially designed to resist the flow of electric current, acting as a protective barrier between individuals and potentially hazardous electrical equipment.

Why does the marine industry hugely depend on an insulated ground mat?

An insulated ground mat is a safety gear that protects the operators working with high voltage appliances. It acts as a barrier between the ground and the high voltage source.

In case of a self adhesive rubber safety mat, you get ready adhesion. It offers easy and hassle-free installation that saves your time and labor costs.

The electrical rubber mat price varies with their specifications.

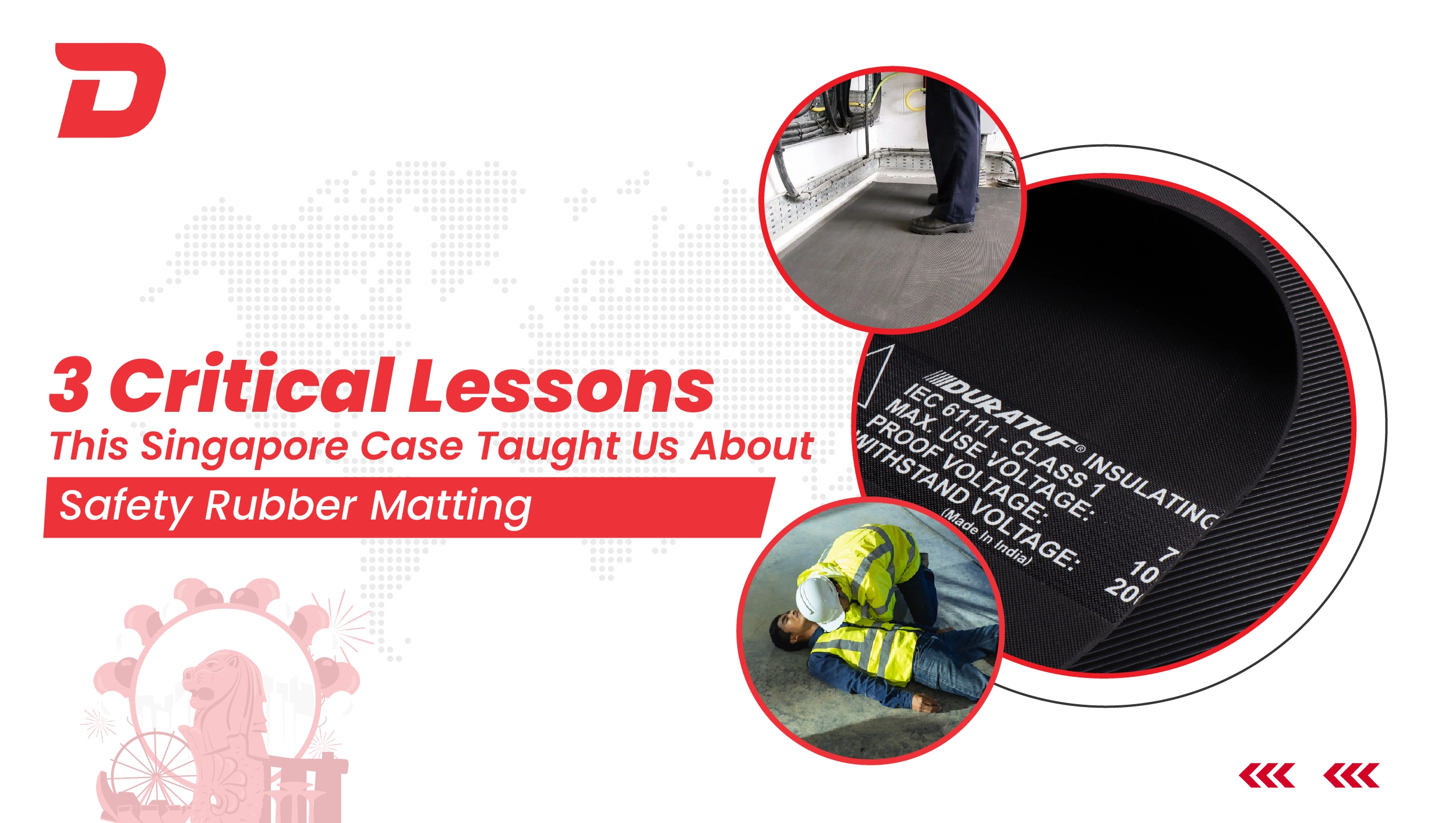

The shock-proof nature of a shock-proof rubber mat is instrumental in preventing electrical accidents, making it a vital component in maritime safety protocols.

3 Reasons to Use an Electrical Mat in Marine Applications

Safety First: Mitigating Electrical Hazards

The marine industry operates in a unique environment, often exposed to harsh weather conditions and corrosive elements.

Electrical hazards pose a constant threat, making the use of a rubber mat for electrical panel a non-negotiable aspect of safety protocols.

Here are some common high-voltage areas found in ships:

Engine rooms house various electrical systems, including propulsion systems, generators, and auxiliary machinery.

High-voltage equipment such as main switchboards, generators, and transformers are often located in these spaces.

Electrical panels and switchboards

High-voltage switchboards control the distribution of electrical energy to different sections of the vessel.

- High-voltage motors, controllers, and power distribution equipment

Spaces dedicated to power generation, where generators and associated equipment operate at high voltage.

Generators and associated switchgear

Control rooms on ships manage and monitor various ship systems, including those operating at high voltage.

Sophisticated control panels and monitoring devices

Areas housing navigation and communication equipment

Radar systems, communication transmitters, and navigation electronics

Cargo handling areas on certain types of ships, such as container vessels,

Cranes, conveyor systems, and other cargo-handling machinery

Systems providing climate control throughout the ship may include high-voltage components.

Motors, compressors, and control systems in HVAC units can operate at elevated voltage levels.

By investing in a shock-proof rubber mat, marine industries prioritize safety, creating a work environment where employees can perform their duties without the constant worry of electrical accidents. Thinking about an electrical rubber mat price? Contact us for a quote!

Compliance with Regulations: Meeting Safety Standards

Adhering to safety regulations and standards is not just a formality; it’s a commitment to creating a secure workplace.

Shock-proof rubber mats align with these regulations, especially in areas where electrical panels are prevalent.

Compliance ensures that an electrical mat meets specific criteria for electrical resistance, flame resistance, and mechanical properties.

Choosing a rubber mat for electrical panel that adheres to safety standards is a proactive measure that strengthens the safety framework in the marine industry. You should never go by the electrical rubber mat price only, but check the quality first.

Enhanced Productivity: Minimizing Downtime

Beyond safety, an electrical mat contributes to the overall efficiency of marine operations. The prevention of electrical accidents minimizes downtime caused by injuries or equipment damage. Hence, allowing for uninterrupted workflow and reducing the financial impact of unexpected disruptions.

In a maritime setting where time is of the essence, the incorporation of a shock-proof rubber mat becomes not just a safety measure but a strategic move to optimize productivity.

What About the Electrical Rubber Mat Price?

Concerns about the cost of safety measures are understandable, but when it comes to an electrical rubber mat, the investment is relatively small compared to the potential risks they mitigate. The electrical rubber mat price is a small expense when weighed against the significant safety benefits they provide.

A Duratuf Electrical Rubber Mat is not as an expense, but a strategic investment in the long run:

The cost of accidents, injuries, or damage to equipment due to electrical malfunctions far outweighs the initial investment in these mats. Moreover, compliance with safety standards, such as using the Duratuf shock-proof rubber mat, can result in long-term cost savings by preventing accidents and ensuring a secure working environment.

Choose Duratuf Electrical Rubber Mat, Because:

Enjoy Hassle-Free Installation of Duratuf Electrical Rubber Mat

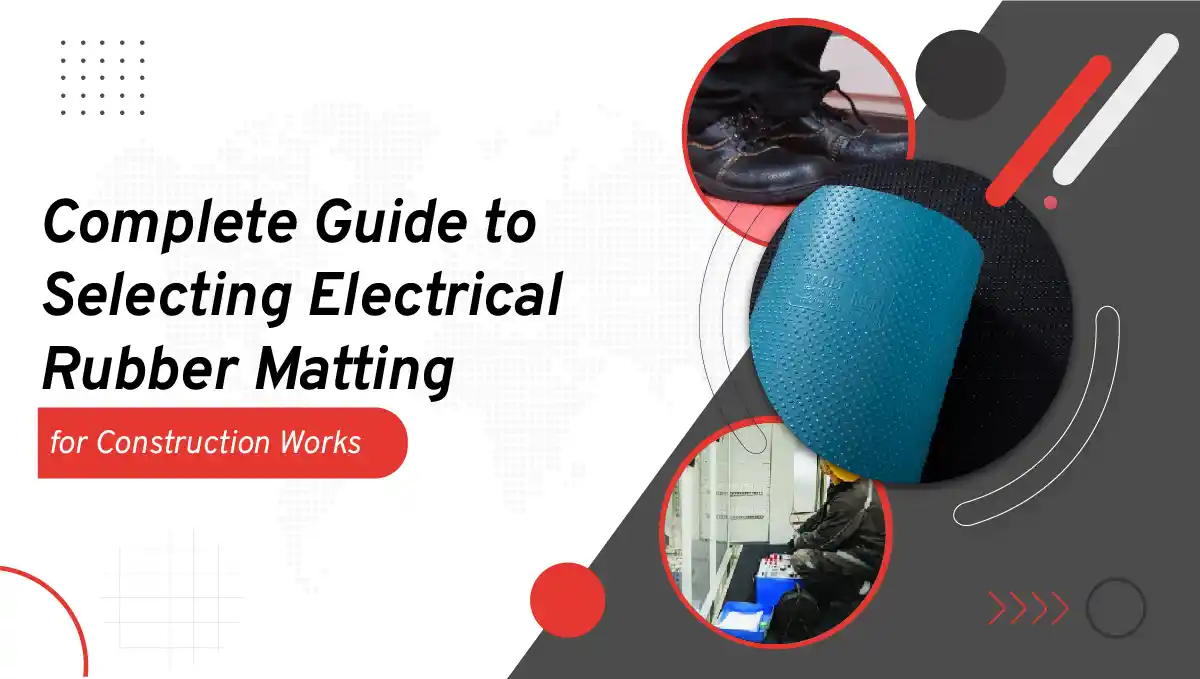

Available at a competitive electrical rubber mat price, the Duratuf rubber mat for electrical panel is easy to install as well:

First, begin by preparing a clean and dry surface, free from any debris.

Second, position the mat in the desired location, ensuring it covers the entire work area. Third, secure the mat using adhesives or double-sided tape to prevent movement.

Third, align multiple mats seamlessly, avoiding overlaps that could create trip hazards. Finally, conduct a stability test to ensure the mat is securely in place.

In Conclusion

From creating a safe working environment and mitigating potential hazards to preventing slips and falls, Duratuf electrical mat plays a multifaceted role in safeguarding personnel and equipment. You can tailor-make a 50 mm floor insulation or alter any other dimensions of your insulating mats with our customization option.

The investment in electrical rubber mats is not just a prudent safety measure; it’s a commitment to the well-being of individuals operating in high-voltage areas and the overall resilience of the maritime infrastructure.

Contact us for quotes!