How to Select Electrical Rubber Matting for Construction Sites

Did you know the construction sector is predicted to reach USD 16.10 trillion by 2030, with a CAGR of 5.9%? Are you a part of this sector? Are you happy with your business profits? Do you believe that there might be a chance for you to grow further? We believe, that electrical rubber matting can help you with that!

According to the OSHA and other sources, electrical injuries are the fourth leading cause of death in the construction industry. There are 0.8 deaths per 100,000 full-time workers!

If you want to explore the true potential of your business, then you have to be attentive about all the aspects of any construction project. From planning it practically to marketing it right- does success come this way?

Well, we think that the more productive your workplace is, the more profitable you will be. This is why we have developed this complete guide for selecting the right rubber safety mats, aka, rubber mat for electrical applications.

Why do you need electrical rubber matting in your construction project?

An electrical rubber mat is made of elastomer. It is designed as protective equipment that can save workers from electric shocks. They have other functions like:

- Safety mats electrical provide insulation against the live current up to a defined voltage.

- A rubber mat for panel room usually complies with national and international safety regulations. Hence, keep you legally safe.

Talking about the applications of electrical rubber matting in construction projects, you can place them, especially near high voltage equipment. The places where rubber safety mats for electrical safety installed, are:

What are the applicable safety mats electrical standards for your construction projects?

A rubber mat for electrical applications is available in three standards:

| Standard | Region | Key Feature |

|---|---|---|

| IS 15652:2006 | India | Voltage-wise classification (Class A, B, C) with anti-skid texture |

| IEC 61111:2009 | International | Class 0 to 4 insulation mats, based on working voltage |

| ASTM D178 | USA | Type I (non-oil resistant), Type II (oil, ozone, and flame resistant) |

Pro tip: While selecting electrical rubber matting ensure the mat has certification from accredited labs (e.g., ERDA, CPRI, NABL).

What are the key features that you should look for in your rubber safety mats?

Electrical rubber matting is an expensive investment, both in terms of money and efficiency. Let us simplify. Imagine you have spent some money on buying electrical rubber mats for your business.

Now, if they are not of good quality or do not provide adequate protection, you will again have to lose money to manage workplace injuries, fatal accidents, and death.

Does not sound very convincing, right? Thus, here are the features your safety mats electrical should have:

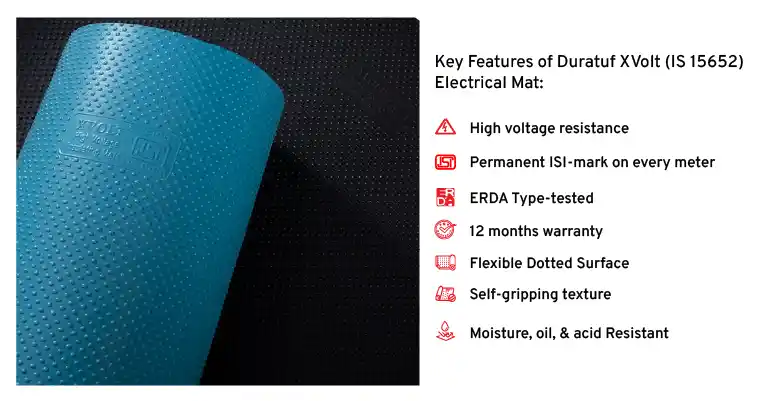

- High Dielectric Strength: Confirms mat can withstand voltage surges.

- Flame Retardant: Essential in fire-prone areas.

- Anti-Skid Surface: Prevents slipping on wet/uneven surfaces.

- Low Acid, Oil, and Alkali Permeability: Especially under ASTM D178 Type II.

- Moisture & Water Resistance: For outdoor/temporary site use.

- Mechanical Durability: Should endure rough use at construction sites.

How to install a rubber mat for electrical applications?

Once you have bought your electrical rubber matting now comes the time for installation. You must be thinking that you cannot install a rubber mat for panel room without expert advice- right?

You are wrong here! You can very well install rubber safety mats without any added technical knowledge.

- First, clean the floor when you want to place the mat

- Second, ensure mats are placed securely without folds or creases

- Third, you can use adhesives but you do not need them for IEC 61111 or ASTM D178 electrical mat variants as they are thick

How to store and maintain the electrical mats on construction sites?

Electrical rubber matting is durable, but they can degrade if exposed to high heat, bright sun, or constant moisture. You can store the electrical mats in their original form, packed in HDPE rolls or lay them flat. Nonetheless, since you do not have much space in temporary construction sites, you can keep the mats in roll only.

Inspect mats weekly for cuts, burns, and surface degradation. Use mild detergents; avoid harsh chemicals that may reduce insulation. For replacement, follow manufacturer guidelines. Replace the rubber mat in electrical room every 3-5 years or post-damage.

How do you choose the right electrical rubber matting supplier?

We say this is the hardest part of all because this is the base of buying good quality electrical rubber matting. Here is how you can do it easily:

Pro Tip: Work with electrical rubber matting suppliers who can offer both IS and IEC-compliant mats if your projects span across geographies.

To Conclude,

The construction sector is booming right now. You can surely grow equally if you do things rightly. Rubber mat in electrical room can be seen more commonly in power distribution units. However, its use is not limited to the energy generation sector only.

An electrical mat is a type of protective equipment that will minimize electrical accidents at your worksite, hence maximize productivity.

In case you are looking for a reputed supplier, call us!