Dielectric Mats for Electrical Panels: Safety, Compliance & Risk Control

Walk into any industrial facility, whether it is a manufacturing unit, a steel plant, or even data centres- one thing you will find in common. Big, buzzing machines running on high electricity. See again, closely. How many places among them, do you think, will have dielectric mats for electrical panels?

Electrical panels are the heart of any industrial or commercial facility. They keep the places running. The same panels can cause deadly accidents if you do not use adequate protection when going near them. But accidents are uncertain.

Therefore, many users think- is it necessary to use an insulation mat for electrical panel? What happens if you do not?

We will tell you what happens if you do not use electrical safety mats for protection in this blog. Here is the crisp but detailed information you need to know as an industrial facility manager, supervisor, or site engineer in 2025.

Dielectric Mats for Electrical Panels Provide 5-Point Safety

Safety is not a requirement in modern workplaces. It has now turned into a crucial business necessity. More industries are now relying on high-voltage machines. Machines have become smarter- AI-powered, demanding significantly more electricity to run than the traditional ones. An IEA report (Energy and AI) highlights that electricity demand will be more than doubled by 2030 to around 945 terawatt-hours (TWh).

As a result of this advancement, electrical accidents are also rising equally.

Below are the essential 5-point safety features an insulation mat for electrical panel offers:

1. Tackling the Hidden Risks Below your Feet

Electrical hazards do not announce themselves before coming. Instead, electrical failures occur when you are least expecting them.

Do you know that the floor where you are standing while operating high voltage machines is the most unsafe place? Especially, without electrical insulation matting?

A minor insulation failure, an unnoticed leakage current, or a technician working in damp shoes is enough to turn a regular workday into a life-threatening emergency.

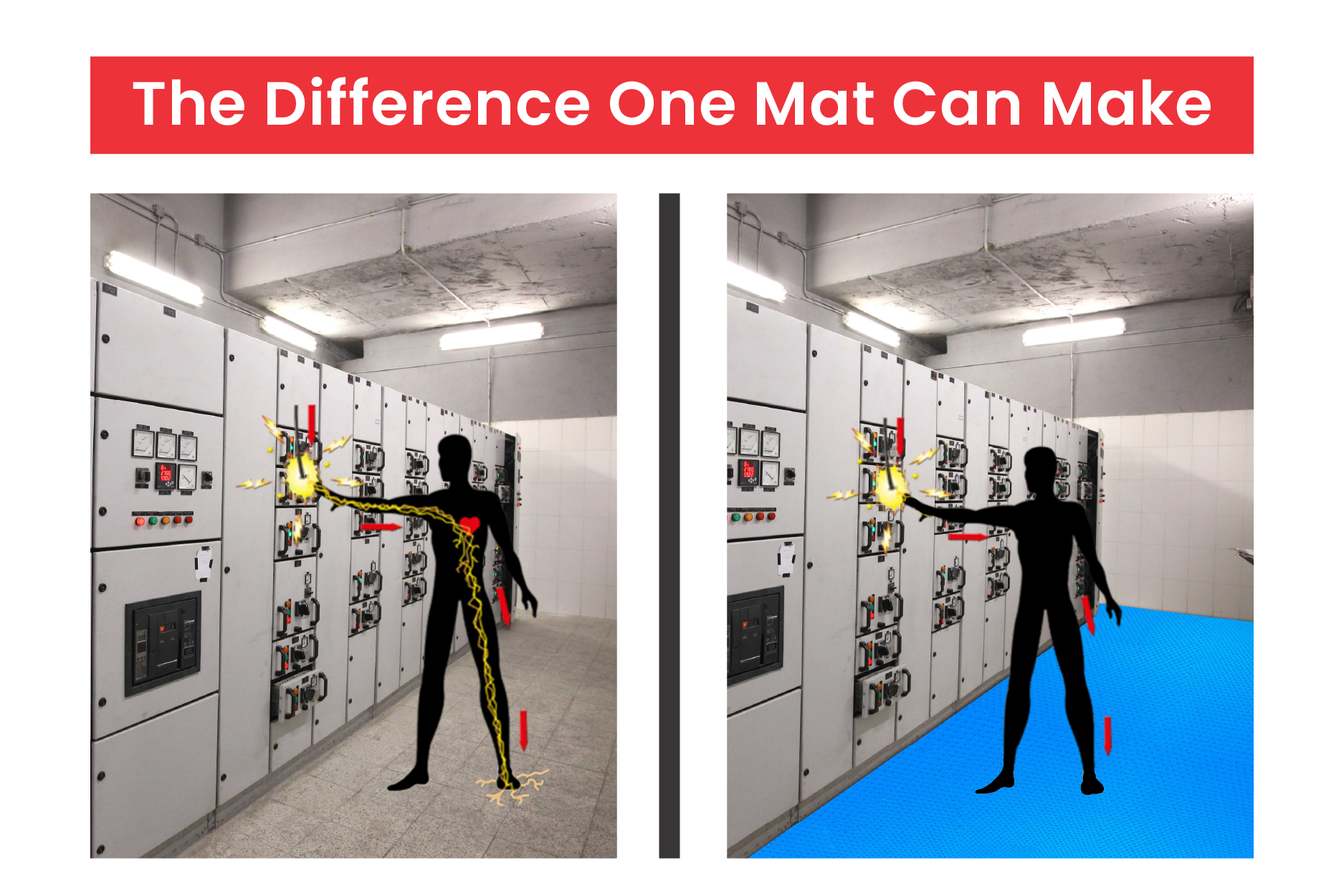

The ground or the Earth is a natural conductor. Human bodies, too. This is why, if you touch live wires, they will pass through your body to the ground.

Dielectric mats for electrical panels break the chain. It becomes a barrier between the human body and electricity.

Pro tip: Machines operate on different voltage levels, like 1 kV, 10 kV, 36 kV, and more. To get adequate protection, choose electrical safety mats of the right class.

2. Establishes a Culture of Responsibility

The global compliance standards for insulation mat for electrical panel are the IEC 61111:2009. Regional standards like the IS 15652:2009 (India) and ASTM D178 (USA) are also there. But in 2025, it is not about checking a box by getting electrical safety mats. It is how you maintain a culture of responsibility as a leader.

Workers are now more aware of their rights. Hence, you cannot shake off your responsibility if there is an accident. Moreover, some labor organizations like the HSE impose hefty fines on the owners if they are found negligent about taking the right safety measures.

A facility that places electrical floor mats safety rated at every electrical panel sends a message: “We don’t just meet standards—we protect our people first.”

This culture boosts trust, retention, and even brand reputation.

3. Protects Owners from the Cost of Neglect

Dielectric mats for electrical panels are not cheap. One roll often costs Rs 1000 on average, approximately. Why would you invest in something so costly for accidents that might not even happen?

Now, consider this:

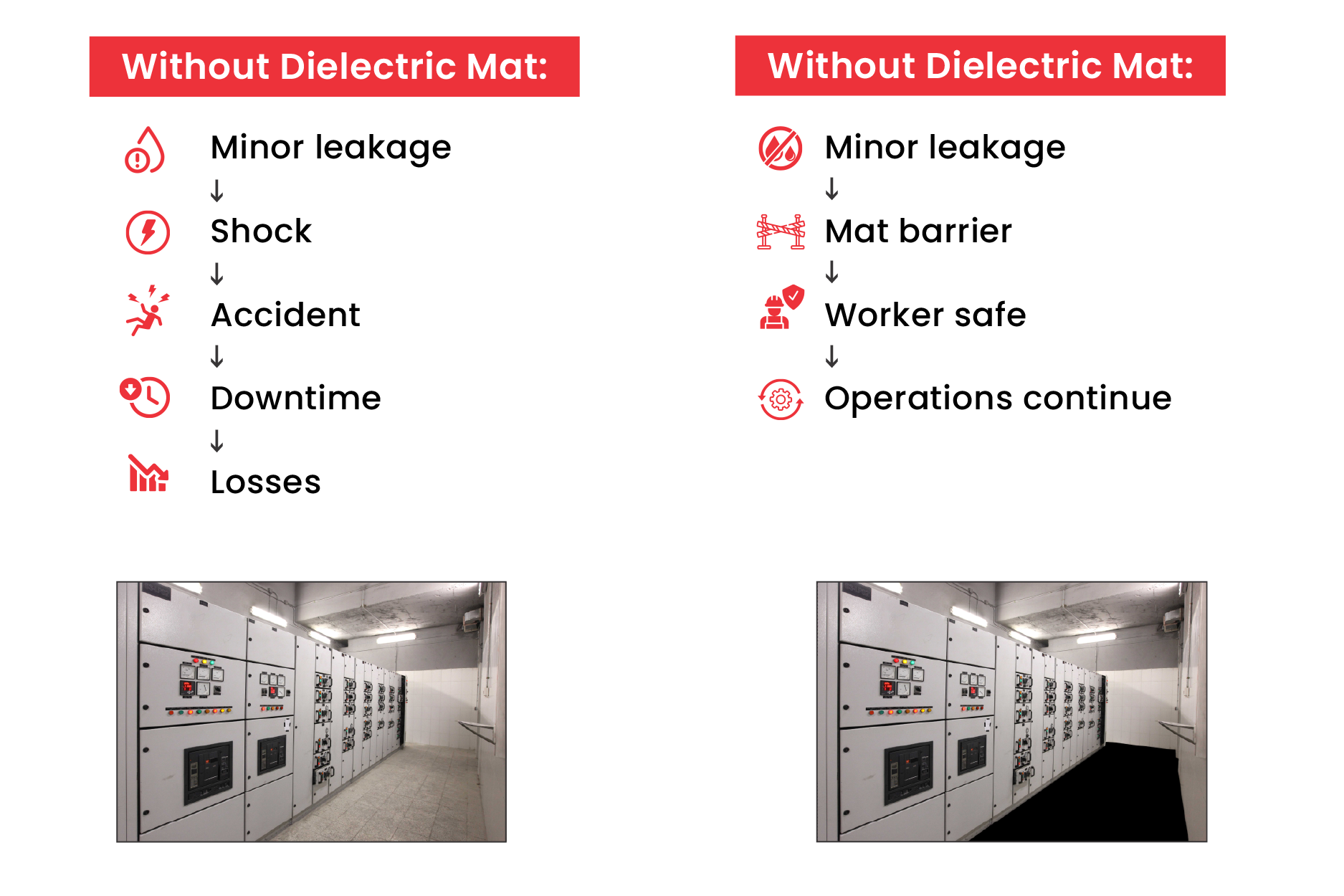

- One electrical accident → downtime, compensation, penalties, morale loss.

- One dielectric mat → a fraction of that cost, and potentially a life saved.

Which one seems costlier? Of course, the accidents. Anti static electrical safety mats, on the other hand, may be costly upfront, but they are not if you think about the long run.

Insulating mats for electrical use save the owners from the cost of neglect.

4. Built for All-round Industrial Needs

Do you think insulation mat for electrical panel saves you from electrical accidents only? Well, you might not be right because electrical safety mats serve all your round industrial needs.

Today’s electric mats are engineered in a way to face even the toughest industrial situations, with features such as:

- Anti-slip texture for oily floors in factories.

- Chemical resistance for labs and refineries.

- Fire retardancy for high-risk zones.

- Heavy-duty durability for 24/7 operations.

Pro tip: All anti-static electrical safety mats may not have all the features together. For example, ASTM D178 Type I mats only resist electricity, but ASTM D178 Type II can withstand UV, Ozone, and Oils.

5. A Safety Net in the Harshest Environments

Industrial floors face heavy foot traffic, oil spills, dust, and temperature fluctuations. The floors degrade faster with vibration from the machines and mechanical strain.

Dielectric mats for electrical panels are designed to withstand these conditions while retaining their insulating properties.

IEC 61111 insulation mats for UAE or Middle East industries safeguard the industrial floors in the harshest environmental conditions, especially in the Gulf nations. If you are looking for only a rubber flooring sheet, you will get lots of options in rubber sheets, like the natural rubber sheet. However, they will not provide you with electrical insulation like the electrical safety mats.

Where Should You Install Anti-static Electrical Safety Mats: Industry-wise Breakdown

Industries worldwide are embracing the importance of using adequate electrical protection in the workplace. However, some of them are stricter about using an insulation mat for electrical panel.

Below is the list of industries that are already using the mats and their application areas:

- Power generation & distribution plants – near switchgear and control rooms

- Oil & gas facilities – explosive environments with high-voltage panels

- Manufacturing units – CNC machines, heavy presses, and automation lines

- Chemical industries – where leakages and spills increase shock risks

- Data centers & telecom hubs – to protect staff maintaining live panels

Final Thoughts,

Accidents happen unannounced, but in 2025, they can get viral in minutes. Today, workers are more alert and know their rights well. On the other hand, regulators demand zero tolerance for negligence. Thus, dielectric mats for electrical panels are no longer optional.

Looking for certified insulating mats for electrical use? Book your free consultation with our specialist now!

Here are some FAQs for you:

How many types of electrical mats are there?

Electrical mats are of three types, typically – IS 15652, IEC 61111:2009 and ASTM D178. However, these are the safety compliance standards rather than just names.

What happens without an electrical mat?

Electrical safety mats keep the workers safe near high-voltage machines like electrical panels, LT-HT panels, Switchboards, etc. Without an electrical mat, the workers may get electric shocks from live wires.

Where can you buy certified insulation mat for electrical panels online?

Certified insulation mat for electrical panels online are available at Ecommerce stores like Amazon, brand stores like Duratuf, and at Trade Portals.

How to identify best anti-static electrical safety mats for factories?

Best anti-static electrical safety mats for factories are tested as per compliance standards IEC 61111, AATM D178 or IS 15652. They come with test certificates.