Humidity & 5 Factors that Reduce Effectiveness of Electrical Safety Mats

Do you want to enhance the life span of electrical safety matting but getting no practical solutions? Have you ever thought about how changing climatic conditions can affect your electrical safety mats?

As experts dedicated to reducing electrical hazards, we get it – the pains of dealing with issues that can affect the lifespan of safety equipment. So, in this blog, we will talk about 5 common elements that degrade the insulation mat for electrical purpose you are using. Since the climatic pattern has become so dynamic, our special focus will be on the effects of humidity. Your key takeaways from this blog will be:

- Humidity and Electrical Properties of Electrical Safety Mats

- Effects of Humidity on the Electrical Mats

- Five Common Elements Affecting the Performance of Electrical Safety Matting

- How Can you Protect the Insulating Rubber Mats from their Enemies?

Imagine what may happen to a worker if they operate high-voltage machines without proper cover. An electrical insulating mat is the base of safety. Whether you use other types of personal protective equipment like gloves, helmets, or jackets, without safety mats electrical flooring, you cannot control the risks.

Electrocution, worker death, or minor injury at the workplace questions the credibility of the management.

Insulating mats for electrical purpose are the base of safety. If you fail to protect such critical safety gear, the consequences might be havoc.

Humidity and Electrical Properties of Electrical Safety Mats

Electrical safety matting is designed to protect workers from electric shock. Water is a good conductor of electricity.

While rubber works as a superior electrical insulator, if moisture seeps in through an electrical insulating rubber mat, it may not provide foolproof safety.

Moisture can create a thin film on the safety rubber matting, reducing the mat’s dielectric strength and increasing the chances of current leakage.

Effects of Humidity on the Electrical Mats

In some areas, like South America, Southeast Asia, or coastal regions, high humidity is a concern:

- Contaminated Surface: The thin film of humidity on the insulating mat makes its surface slippery. Dust, debris, and other contaminants stick to the electrical mats.

- You may notice pinholes, eroded surfaces, and edge warping out of nowhere.

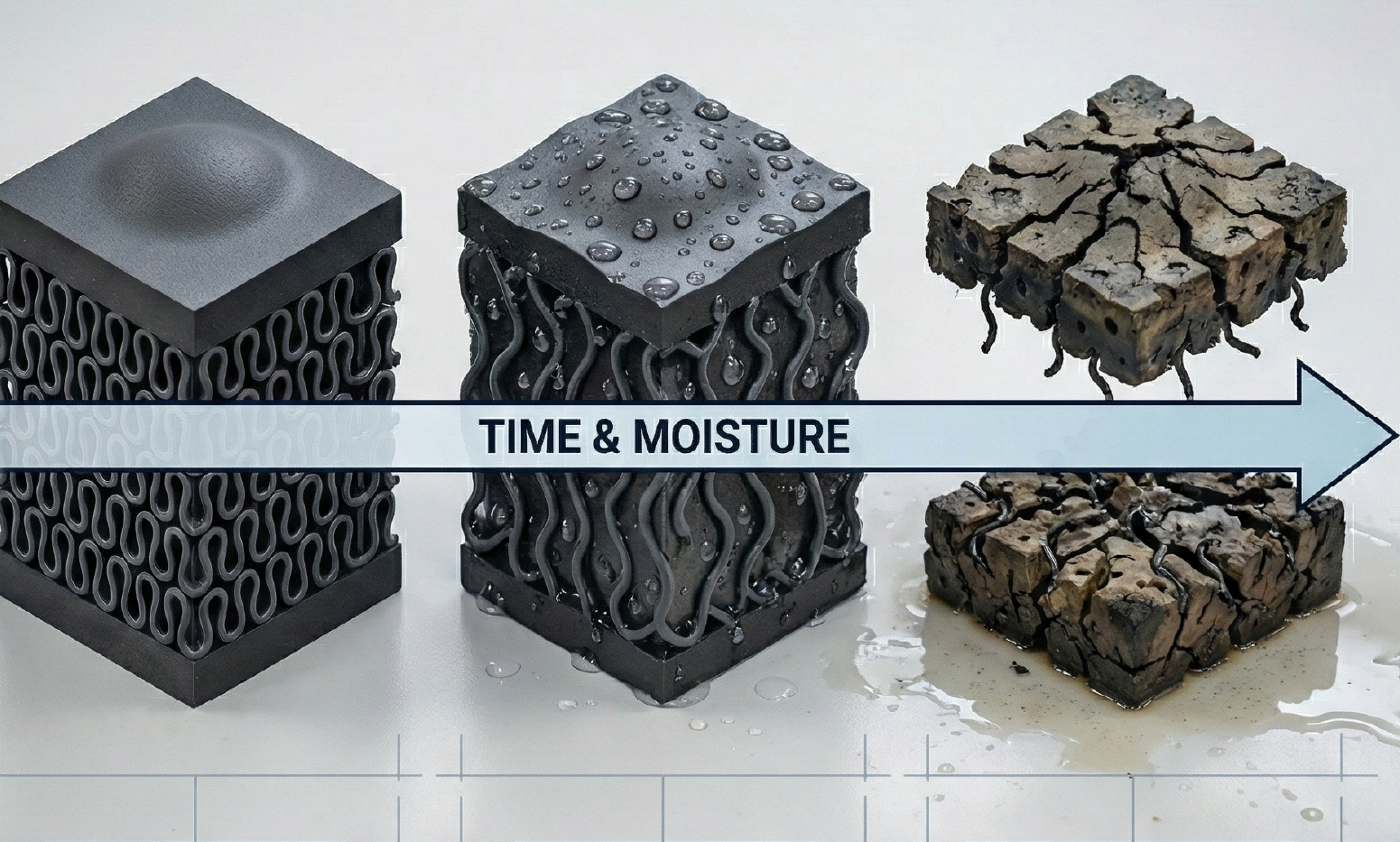

- Moisture Absorption: The electrical rubber mats absorb the moisture as it seeps through its layers.

- A major problem with rubber is swelling. Water causes swelling and formation of bubbles in the insulating mat.

- Material Degradation: Continuous exposure to humidity, even rainwater, induces fast breakdown of rubber polymer compounds. Using faulty insulating mats for electrical purpose means inadequate safety cover in high-voltage environments.

Five Common Elements Affecting the Performance of Electrical Safety Matting

Electrical safety mats are used near high-power equipment in electrical substations, in the transformer room, near switch panels, etc.

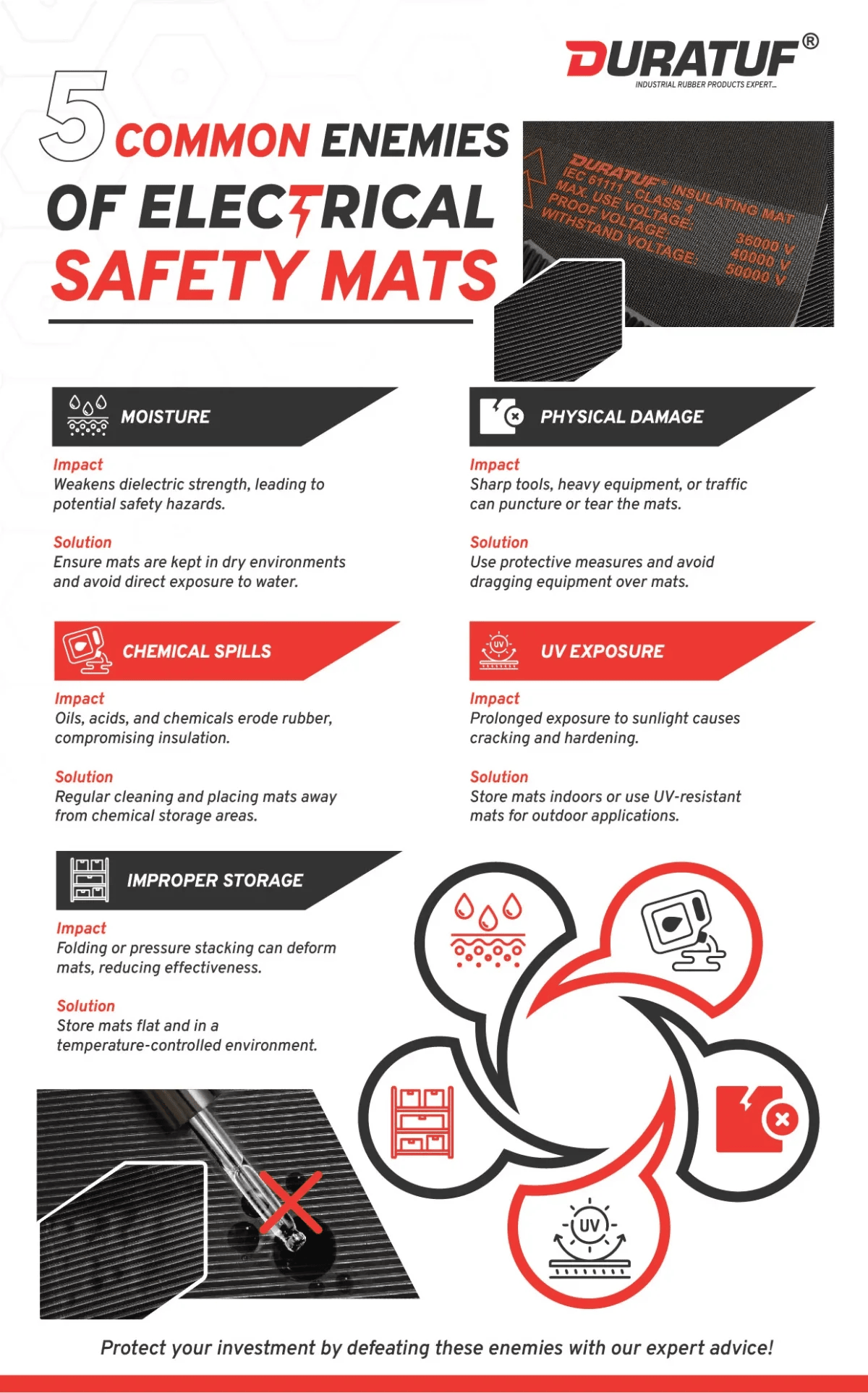

Hence, apart from humidity, these are the 5 enemies of electrical safety matting as per an electrical insulating rubber mat manufacturer.

1. Dust:

Dust messes with the dielectric strength of an insulating rubber mat. Dust reduces the aesthetic appeal of the insulating mats. It causes the electrical mats to lose their grip.

Solution? Regular cleaning!

2. Moisture

When moisture penetrates the mat material, it disrupts the insulation, creating paths for electrical current to flow through.

Since the insulating mats are made from rubber, moisture can cause the material to break down over time. This is why aged electrical safety mats do not offer 100% electrical safety.

Solution? Get a moisture-proof insulating rubber mat!

3. Strong Chemicals

Strong chemicals, such as acids, solvents, and corrosive substances, are not good for electrical insulating mats. Additionally, the color of the electrical insulating mats also fades away when they come in contact with highly corrosive substances.

Solution? Keep electrical safety matting away from strong chemicals or buy a mat designed for heavy duty performance.

4. Improper Maintenance

Even the strongest electrical insulating mats have a weak spot – it’s called improper maintenance. Forgetting to check them weakens their power, making electrical problems more likely.

Solution?

Electrical safety matting does not require rigorous maintenance. You just need to clean and regularly inspect them to keep the electrical hazards at bay.

5. Delayed Safety Checks

With time, the composition of the compounds gets altered. A long gap between safety checks lets problems grow.

Moreover, with an aged electrical safety mat, your responsibility for maintaining workplace safety might also be questioned.

Your competitors might take advantage if your workplace is prone to electrical hazards.

Solution? Quick and regular checks are like a practical move – catching problems before they get big.

How Can you Protect the Insulating Rubber Mats from its Enemies?

Can you protect the insulating rubber mats from humidity?

The good news is yes. To ensure that electrical mats work as expected in a highly humid environment, follow these tips from our electrical mat specialists:

- Buy a ‘certified’ electrical mat: Certifications guarantee that you are buying a good-quality product. Electrical safety mats are only certified after several rounds of quality testing. In the process, the mats are tested for their dielectric strength and voltage performance.

- Inspect the mats frequently: You can inspect an insulating mat without the help of a professional inspector. Check visually for the accumulation of moisture on the electrical rubber mats.

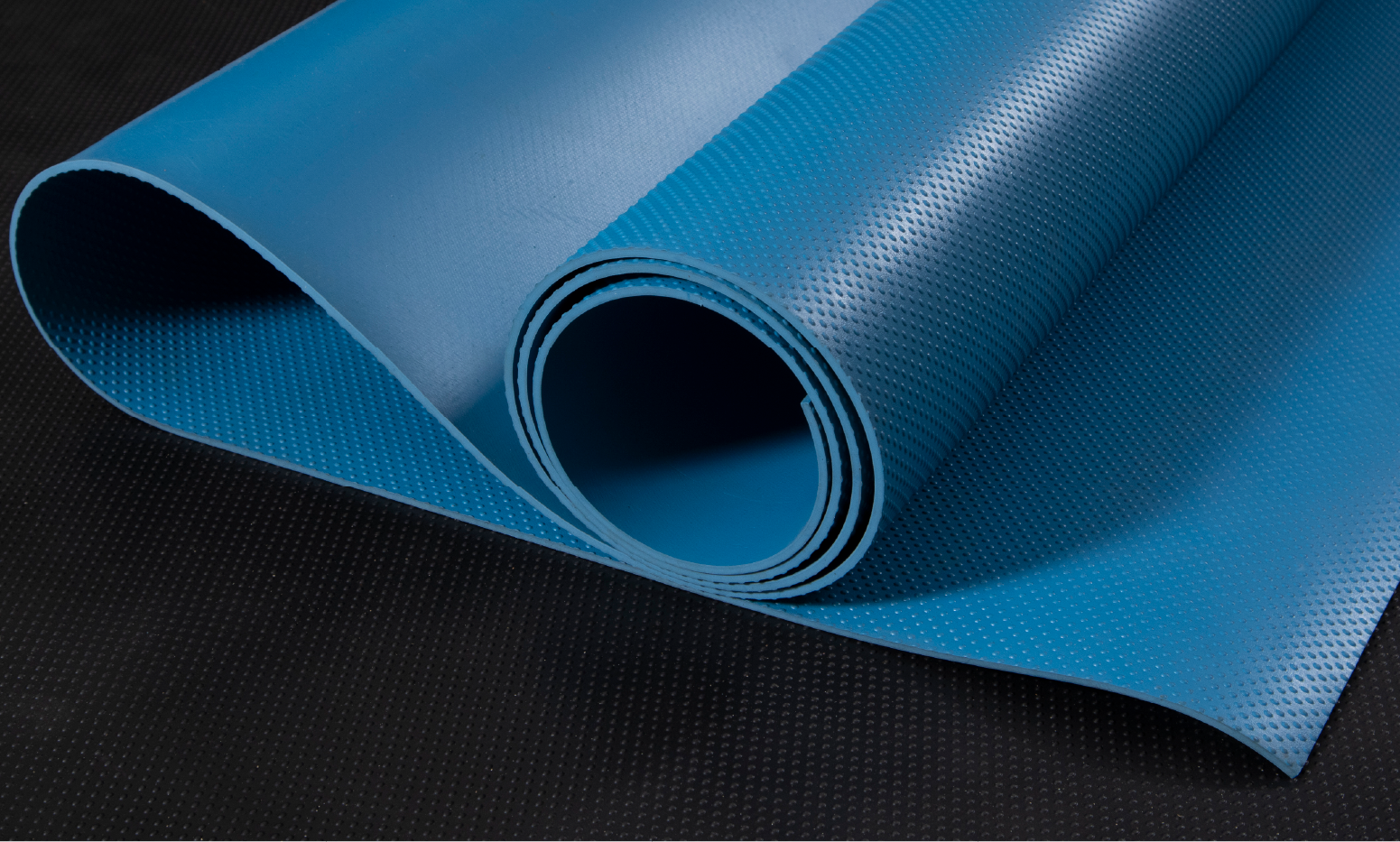

- Store the mats properly: Buying insulating rubber mats in bulk is always a good decision. Bulk buying saves time and money. But the challenge starts after you buy electrical mats in large quantities. Store the mats in cool and dry places.

- Ventilated storage areas: Ventilation systems in the storage areas ensure there is good air circulation in the place. The electrical mats in their plastic packages can sweat due to the effects of humidity. Ventilation reduces condensation and thus the overall impact of humidity.

In Conclusion,

Defeating the enemies of electrical safety matting is not just a job – it’s a promise. By being smart, taking care of safety mats, and doing safety checks, you give insulating mats the power to keep everything safe.

It’s not just about the workplace; it’s about making sure everyone goes home safe and sound.

Looking to buy an insulation mat for electrical purpose? Consult with our product expert today.