Safety Rubber Matting: 3 Critical Lessons from a Singapore Case

Did you know how electrical accidents are common- even in the most safety conscious countries like Singapore? The smallest mistake around live panels can turn out to be fatal. But, what happened in this Singapore factory that taught us 3 critical safety lessons about an electrical safety rubber mat for electrical panel?

Singapore is one of the few places in the world that has the most stringent rules about workplace safety. The Ministry of Manpower envisions being a global leader in WSH practices with ‘Vision Zero’- zero injury and ill-health at work.

However, a recent case study, published by the Energy Market Authority (EMA), has left us thinking about negligence regarding electrical safety. What happens when protective equipment like electrical mats are not used?

First, let’s look at what happened and what solution the EMA gave:

What is this case study all about?

Case study number 5, published by the Energy Market Authority, talks about an incident when a worker got electrocuted. He was fatally electrocuted while installing current transformers (CTs) on a 300-Amp MCCB in a switchboard. A nearby 500-Amp MCCB was live and serving circuits. During the task, the worker’s shoulder accidentally touched a live terminal of the energized 500-Amp MCCB, resulting in a fatal electric shock.

Why the accident?

The EMA has found that there were no proper insulating barriers present when the worker was handling high voltage.

What solution did the EMA propose?

EMA has proposed two rightful and easy solutions.

- Switching off the 500-Amp MCCB when not in work

- Using suitable ‘insulating barriers’ like an electrical safety rubber mat for electrical panel

(Resource: https://elise.ema.gov.sg/eguides/case_study_5.pdf)

While this case is tragic and acts as an example, it also points to something important- the need for the right protective equipment. A prime and most commonly used option is a Safety rubber matting electrical product.

We unpack three key takeaways from this incident that reinforce the vital importance of using safety rubber matting electrical in commercial and industrial workplaces. Here they are:

3 key reasons why Electrical Safety Floor Mats are a must in industrial workplaces

In this case study, we have learned about the unfortunate fate of a Singaporean worker. As a rubber mat supplier in Singapore, we feel that this incident and many can be averted with the right equipment. Here’s why we suggest using a safety rubber matting electrical product in all industrial workplaces:

Safety rubber matting and electrical variants are not optional

One of the most critical reasons behind this accident was the absence of a dry electrical safety rubber mat for electrical panel while working. The EMA points out that insulating barriers should always be there because they are the first line of safety for the workers.

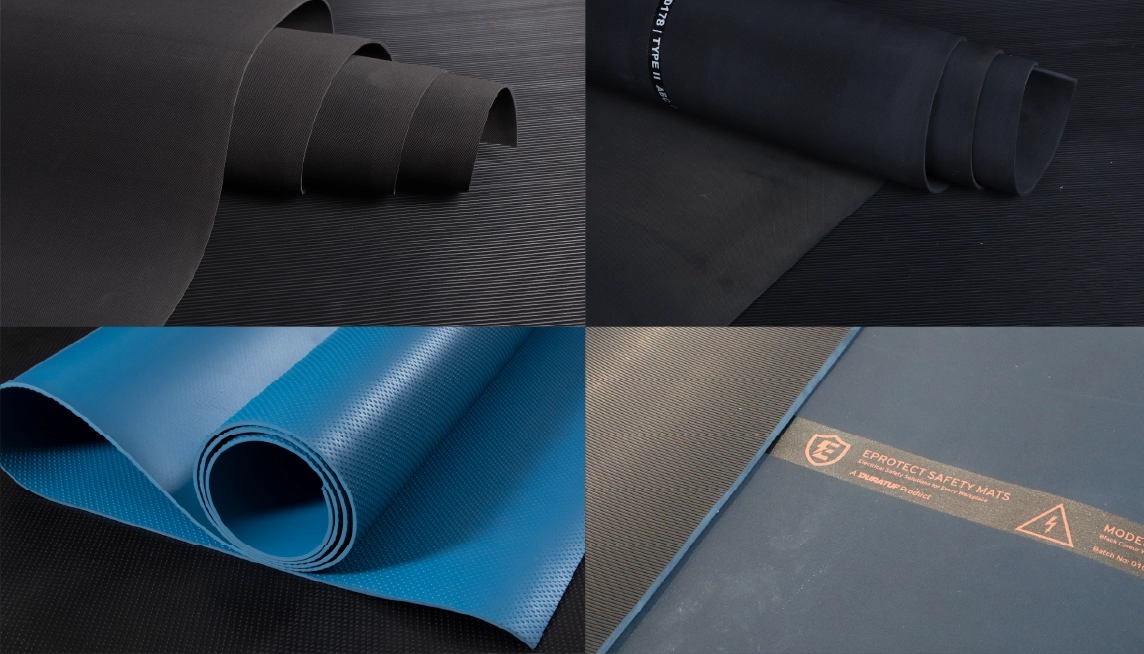

The insulating mat should be safety-certified. It should adhere to the IEC 61111:2009, IS 15652, or ASTM D178 rubber mat standard for electrical panel. These are compliance standards that talk about the dielectric strength, dimension and use cases of the mats.

Nevertheless, apart from electrical mats, workers should wear other protective gear like rubber gloves, dielectric boots, helmets, and arc-flash jackets.

Insulating mats should be part of a larger safety system

This electrical accident was not only the absence of insulating mats, but also the absence of other electrical protective gear, as well. It was part of a broader failure in implementing safety procedures such as risk assessment, lock-out/tag-out (LOTO) protocols, and supervision. The lack of electrical mats was just one gap—but one that multiplied the danger.

As a responsible business owner or a safety manager, you should build mats into your Pre-Work Risk Assessments (PWRA) and Job Hazard Analysis (JHA) checklists.

Quality safety rubber matting electrical variants, prevent slips, trips, and falls

According to OSHA, slips, trips, and falls can cause more than 700 workplace fatalities every year. Singapore has a humid climate and receives a large amount of rainfall each year. This makes the floors slippery and prone to slips, trips, and falls.

Electrical safety floor mats, if designed well, can offer you dual action. First, protecting you and your workers from electrical accidents, and second, acting as an anti-slip floor cover. Additionally, electrical mats provide lower leg comfort to the workers who have to stand on their feet for long hours.

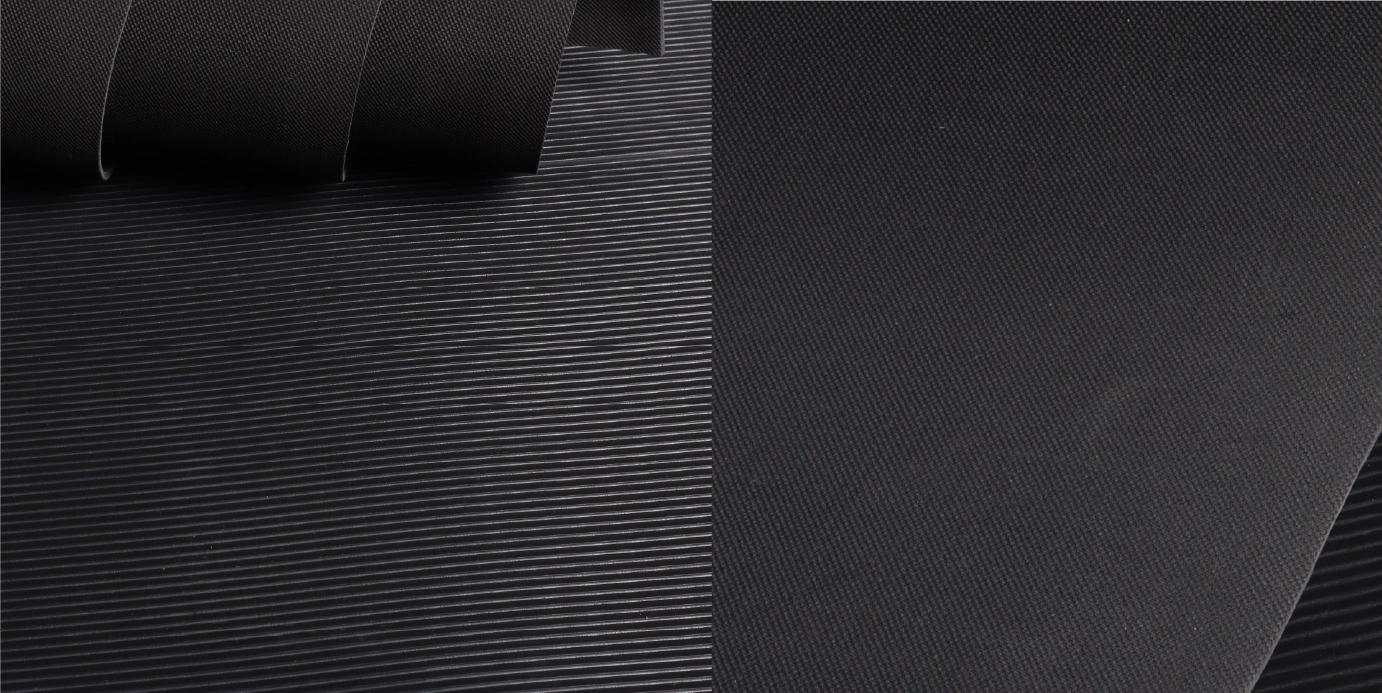

Electrical mats have ribbed or dotted surfaces to make them anti-slip.

Why is an electrical safety rubber mat for electrical panel considered protective equipment?

An electrical safety rubber mat for electrical panel is simply known as an electrical mat or electrical safety floor mats. These mats have dielectric properties due to their composition. An electrical mat is made of a specialized polymer of rubber, Elastomer. It is placed on the floors under electrical equipment that runs on 1 kV and above.

A leading rubber mat supplier in Singapore explains why users consider this product as personal protective equipment:

- First, the composition of electrical mats makes them non-conductive.

- Second, users trust a rubber matting electrical switch room as the ‘base of safety’. Workers feel confident knowing they are standing on something shockproof.

The human body is conductive. Therefore, electric charge tends to pass through the body, injuring the individual fatally.

When a worker standing on an electrical safety rubber mat for electrical panel comes in contact with a live wire, the electricity passes to the ground and not their body. This is because of the elastomer in their composition.

Third, Global businesses are using electrical insulating mats and recommending them strongly.

Final Thoughts,

The Singapore case study has highlighted a hard truth. While here only one worker has faced the accident, thousands of workers worldwide are getting electrocuted regularly. Even in one of the safest countries in the world, like Singapore, a simple piece of protective equipment like rubber matting in an electrical switch room could have made the difference between life and death. Electrical accidents are preventable with the right equipment.

Whether you’re managing a facility in Tuas, overseeing contractors in Changi, or handling energy infrastructure in Jurong, make sure that electrical rubber matting isn’t an afterthought—it’s a frontline defense.

Looking for a quality-certified electrical mat? Contact us!